Shree Aagarsen Steel Industries Pvt. Ltd.

We Help You Stand Stronger | Think of Steel, Think of AAGARSEN

Shree Aagarsen Steel Industries Pvt. Ltd.

We Help You Stand Stronger | Think of Steel, Think of AAGARSEN

Brands We Deal With

We Help You Stand Stronger | Think of Steel, Think of AAGARSEN

We Help You Stand Stronger | Think of Steel, Think of AAGARSEN

We Help You Stand Stronger | Think of Steel, Think of AAGARSEN

Steel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron, but various other alloying elements are used, such as manganese, chromium, vanadium, and tungsten.[1] Carbon and other elements act as a hardening agent, preventing dislocations in the iron atom crystal lattice from sliding past one another. Varying the amount of alloying elements and the form of their presence in the steel (solute elements, precipitated phase) controls qualities such as the hardness, ductility, and tensile strength of the resulting steel. Steel with increased carbon content can be made harder and stronger than iron, but such steel is also less ductile than iron.

Alloys with a higher than 2.1% carbon content are known as cast iron because of their lower melting point and good castability. Steel is also distinguishable from wrought iron, which can contain a small amount of carbon, but it is included in the form of slag inclusions. Two distinguishing factors are steels increased rust resistance and better weldability.

Though steel had been produced by various inefficient methods long before the Renaissance, its use became more common after more-efficient production methods were devised in the 17th century. With the invention of the Bessemer process in the mid-19th century, steel became an inexpensive mass-produced material. Further refinements in the process, such as basic oxygen steelmaking (BOS), lowered the cost of production while increasing the quality of the metal. Today, steel is one of the most common materials in the world, with more than 1.3 billion tons produced annually. It is a major component in buildings, infrastructure, tools, ships, automobiles, machines, appliances, and weapons. Modern steel is generally identified by various grades defined by assorted standards organizations.

Iron is a chemical element with the symbol Fe (from Latin: ferrum) and atomic number 26. It is a metal in the first transition series. It is the most common element in the whole planet Earth, forming much of Earths outer and inner core, and it is the fourth most common element in the Earths crust. It is produced in abundance as a result of fusion in high-mass stars, where the production of nickel-56 (which decays to iron) is the last nuclear fusion reaction that is exothermic, becoming the last element to be produced before collapse of a supernova leads to events that scatter the precursor radionuclides of iron into space.

Like other Group 8 elements, iron exists in a wide range of oxidation states, -2 to + 6, although +2 and +3 are the most common. Elemental iron occurs in meteoroids and other low oxygen environments, but is reactive to oxygen and water. Fresh iron surfaces appear lustrous silvery-gray, but oxidize in normal air to give iron oxides, also known as rust. Unlike many other metals which form passivity oxide layers, iron oxides occupy more volume than iron metal, and thus iron oxides flake off and expose fresh surfaces for corrosion.

Iron metal has been used since ancient times, though lower-melting copper alloys were used first in history. Pure iron is soft (softer than aluminum), but is unobtainable by smelting. The material is significantly hardened and strengthened by impurities from the smelting process, such as carbon. A certain proportion of carbon (between 0.2% and 2.1%) produces steel, which may be up to 1000 times harder than pure iron. Crude iron metal is produced in blast furnaces, where ore is reduced by coke to cast iron. Further refinement with oxygen reduces the carbon content to make steel. Steels and low carbon iron alloys with other metals (alloy steels) are by far the most common metals in industrial use, due to their great range of desirable properties.

Coming Soon

Coming Soon

Coming Soon

Coming Soon

Coming Soon

Coming Soon

Coming Soon

Coming Soon

Coming Soon

Coming Soon

Coming Soon

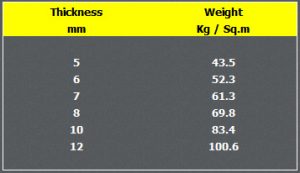

We offer a comprehensive range of galvanized coils, galvanized sheets, and galvanized steel coils, hot dip galvanized coils, galvanized steel sheets, plain steel sheets, corrugated steel sheets, which have carved a niche in domestic as well as overseas market. These GP/GC Sheets comes with zinc coating thickness of 120gsm, lending it great durability. It is the roof that has to take the brunt of natures extremities during its entire life and hence utmost care must be taken in selection of the right roofing material. Wrong choice of roofing and cladding can create losses in terms of human lives and material in cases of natural disasters. A good reliable roof with least number of complications gives peace of mind to meet the challenging needs of the customers. As these sheets are uniformly coated, so corrosion finds no weak spot even when fixing nuts and bolts. And better coating adherence protects the sheets from scratches and other damages.

Applications

Galvanized Sheets are used extensively in various applications. Some of the common uses are: –

Agriculture : Grain Silos, Sprayers, Ghamellas, Pans, Feeding Troughs, etc.

Automobile Cars, Busses, Truck Bodies, Undercarriage Work, Air & Oil Filters, Fuel & Oil Tanks, Exhaust Pipes

Construction Roofing, Side Walls, Partitions, Panels, Valley Gutters, Louvers, False Ceilings, Partition Walls and Ducks, Rolling Shutters, Highway Bumpers, Slotted Angles, Paint-Coated Products.

Domestic Trunks, ice Boxes, Household Machines, Tubs, Pails, Buckets, Storage Bins, Water Tanks, Washing Machines, Bathroom Doors, etc.

Electrical Appliances Air-conditioners, Coolers, Refrigerators. Freezers, Electrical Panels, Decorative Lamps

Furniture & Fixtures Desks, Lockers, Racks, Lightweight Chairs, Colour Coating, PVC Coating

Marking of Coils Ducting, Drums/Barrels, Containers, Thermal Cladding, Air-Conditioning Ducts, Railway Coaches and other Applications

Outdoor Sign-boards, Hoardings, Road Sings

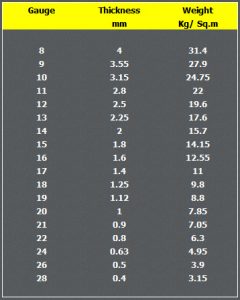

We offer a wide range of Hot Rolled and Cold Rolled Steel Sheets that is available in different width and thickness. Hot rolled coils, sheets are the largest product category in terms of both sales volume and revenue. Hot Rolled Coils are primarily used for making pipes and have many direct industrial and manufacturing applications, including the construction of tanks, railway cars, bicycle frames, ships, engineering and military equipment and automobile and truck wheels, frames and body parts. Hot Rolled Coils are also used as feedstock for cold rolling mills where they undergo further processing.

Our ample range of Cold Rolled Steel Sheets is in high demand, due to their impeccable quality and outstanding performance. We have uniquely positioned ourselves as one of the preeminent supplier of CR sheets in India. Cold rolled sheets are manufactured from the superb quality raw material using the high technology machines. They are available in various sizes & dimension range and can be customized as per the demand of the client. CR Sheets/Coils in various thicknesses & in �D�, �DD�, �EDD� & Stamping quality for use in automobile, cycle, stampings & white goods industries. Excellent formability, good surface quality and tight tolerance power are the unique features of the cold rolled steel sheets.

We also offer Rounds & Bright Bars. Bright Bars are steel or metal bars that are produced by one or more cold finishing processes. The processes outlined below are known as Cold Finish processes or the end products are known as cold finished because there is no or very little heat applied in the entire operation of converting them from hot rolled bars (also known as black bars) to Cold Finished Bars or Bright Steel Bars.

Cold Drawing: Hot Rolled Bar is descaled, pulled through Tungsten Carbide or High Speed Steel Die, straightened & cut-to-length; Improves dimensional tolerance and shape, straightness, surface finish, strength and machinability.

Turning and Polishing: Remove bar surface of Hot Rolled Bars with revolving cutting tool, rotate bar through rolls to straighten and polish, then cut-to-length. Improved dimensional tolerances and removes surface defects and decarburization.

Grinding: Abrasive wheel grinds off surface metal. Improves surface finish and achieves very close dimensional tolerances.

Cold Rolling: Descaled, pass through series of rolling stands, strengthening and cut-to-length. Improves dimensional tolerance and shape, surface finish and strength

They are widely used in Machined Components, Pump Shafts, Valves, Fasteners, Machine Tools, Daily Equipments, Surgical & Medical Parts, Thread Bars, Studs, Bolts, Pins, Hinges and Handles.

We can supply Bright Bars in the following sections –

a) Cold Drawn (Rounds, Hexagons, Flats, Squares)

b) Drawn and Ground Bars (Rounds)

c) Peeled Bars (Round)

d) Turned Bars (Round)

The Thermo Mechanically Treated TMT steel bars also known as reinforcement steel and wire rods are primarily used by the construction industry. Its high-corrosion and rust- resistance features make it the first choice for buildings in costal areas and in areas of high humidity. The manufacturing process of TMT involves 3 stages of treatment – Quenching, Self-tempering and Atmospheric Cooling.

Stage 1 – The reheated billet first gets rolled and is passed through the quenching process where the surface of the bar is instantly cooled to martensite while the core is still austenitic.

Stage 2 – Heat from the core of the bar dissipates to the surface allowing forming tempered martensite, while the core remains austenitic. This process is called self-tempering.

Stage 3 – Due to atmospheric cooling, wherein the bar is cooled on the cooling bed, results in the austenitic core being converted into ductile ferrite-pearlite core; which gives TMT its unmatched qualities of strength and ductility

Its ductility and bend ability on the other hand, makes it the perfect choice for buildings in seismic zones for high-stress construction structures. They find wide application for a number of high-specialty and custom constructions including coastal and marine environments which are susceptible to corrosion and general purpose concrete reinforcement structures like Homes, Apartments, Hospitals, Hotels, Auditoriums, Bridges, Dams, Flyovers, Thermal & Hydel Power Plants, Industrial Structures, High-rise buildings Earthquake-sensitive zones, Underground platforms in Metro Railways and Rapid Transport Systems.

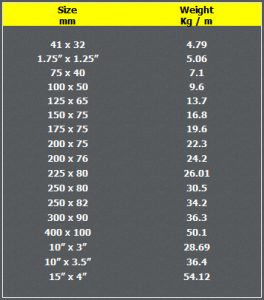

We offer the finest quality Beams/Joists/Girders which is the most sought after sections by the structural engineers, architects and construction companies all over the world. With infrastructure development playing the lead in today�s global scenario Indian engineers and architects are exploring better options to go beyond the conventional norms and to win over the challenges of modern constructions. They are widely used in Industrial Buildings, Multi Storey Building, Road Bridge composite construction, Industrial structures Railways, Ports and Harbour, Offshore Drilling Rigs and in addition to above mentioned utilities, MS Beams/Joists are used in Heavy machinery, industrial boilers, wagon tippers, feeders, stackers, crushers, loaders, cranes, shipping industry and supporting frames for equipment used in metallurgical and other heavy industries.

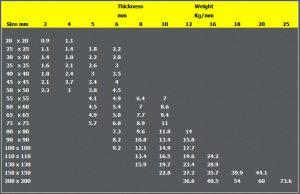

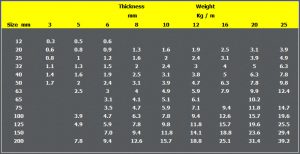

We offer the finest quality MS Angles, which are extensively used in fabrication industry. The dimension is determined by the length and the thickness of the two sides. The most commonly found steel angles are formed at a 90 degree angle and has two legs of equal length. The sides are either equal or of different sizes, if one leg is longer than the other then it is known as UNEQUAL angle. The steel angles of various strength like HT (High Tensile)/MS are formed as required by different applications. These products are used in bracket, trimming, transmission line, framing and reinforcement. Our company also stocks and supplies Tower sections against orders of clients.

We offer the finest quality MS Channels, which are extensively used in fabrication industry. A channel is a right angle “C” section. They are also called C Channels. Along with beams, channels are mainly used in structural applications. Mostly MS Channels are used as supports and guide. These are roll-formed products. MS Channels are usually applied in the automotive industry as well as heavy machinery industries. Generally, there are 3 types of mild steel channel, they are:

1) Plain Channels,

2) Lipped Channels &

3) Universal Channels.

Our range of MS Channels is available in different sizes and dimensions and can also be customized as per the requirements of our clients.